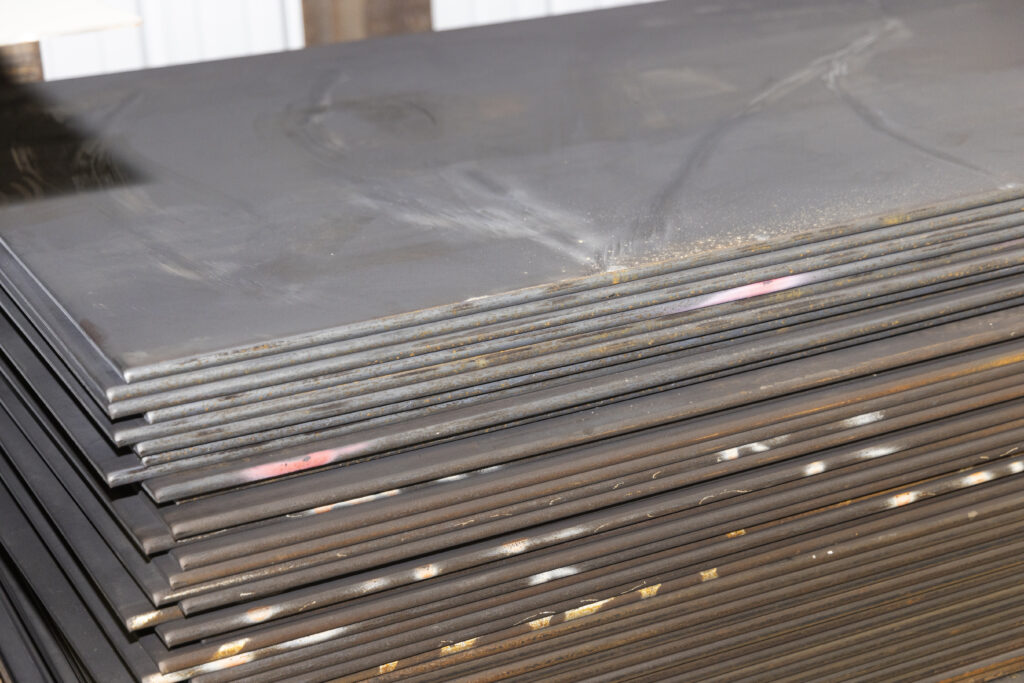

STEEL PLATE

Hot rolled steel plate is a durable and often less expensive option when structural-quality steel plate is needed. This material is perfect for a wide array of general construction and industrial applications, including structural support, walkways, ramps, general fabrication, and transportation equipment. See below for available sizes; if you don’t see the dimensions you’re looking for, just let us know and we’ll be happy to help you find what you need.

4’ x 8’, 1 ¾” thick

4’ x 8’, 1 ½” thick

4’ x 8’, 1 ¼” thick

4’ x 8’, 1” thick

6’ x 10’, ¾” thick

5’ x 10’, ¾” thick

4’ x 10’, ¾” thick

4’ x 8’, ¾” thick

4’ x 8’, ½” thick

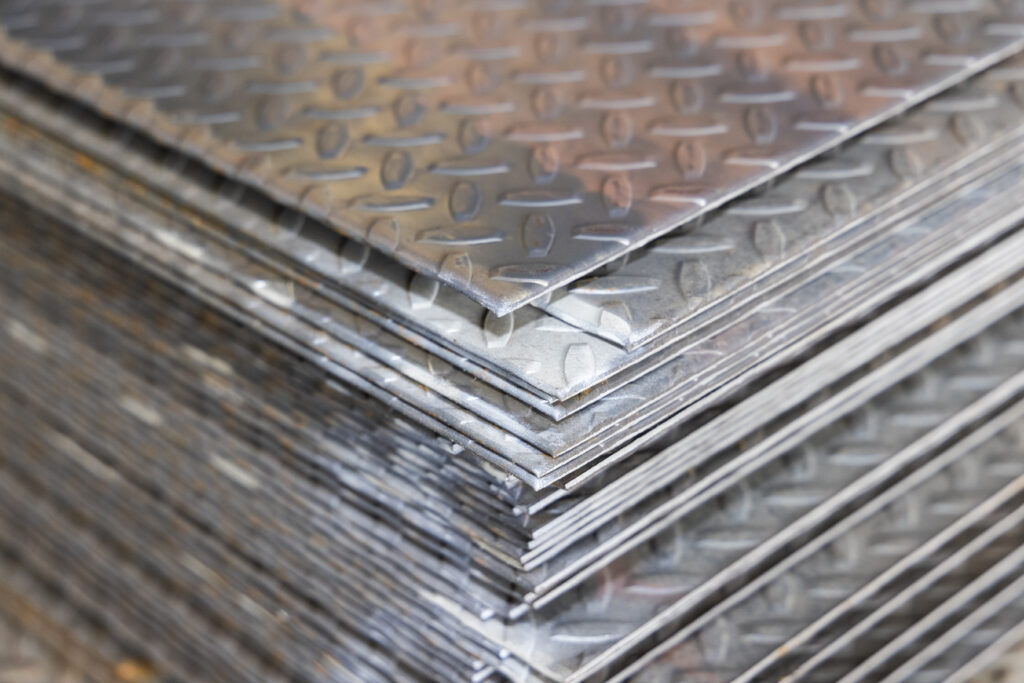

STEEL FLOOR PLATE

Whether you call it steel tread plate, steel diamond plate, or plain old steel floor plate, we have it in every size for every skid-resistance need. Steel floor plate features the signature raised diamond lug pattern designed to increase traction in trailers or truck bed flooring, running boards, ramps, mezzanines, trench covers and more. See below for available sizes; if you don’t see the dimensions you’re looking for, just let us know and we’ll be happy to help you find what you need.

4’ x 8’, ½” thick

6’ x 10’, ⅜” thick

4’ x 10’, ⅜” thick

4’ x 8’, ⅜” thick

5’ x 10’, ¼” thick

4’ x 10’, ¼” thick

4’ x 8’, ¼” thick

5’ x 10’, 3/16” thick

5’ x 8’, 3/16” thick

STEEL SHEET

We carry a large inventory of hot rolled steel sheets, ideal for agricultural implements, automotive equipment, blower systems, ventilation systems, drums, bins, partitions and more. See below for available sizes; if you don’t see the dimensions you’re looking for, just let us know and we’ll be happy to help you find what you need.

6’ x 12’, 10 gauge thickness

6’ x 10’, 10 gauge thickness

4’ x 10’, 10 gauge thickness

4’ x 8’, 10 gauge thickness

6’ x 10,’ 11 gauge thickness

5’ x 12’, 11 gauge thickness

5’ x 10’, 11 gauge thickness

5’ x 8’, 11 gauge thickness

4’ x 12,’ 11 gauge thickness

4’ x 10’, 11 gauge thickness

Ways to Order

- By phone: Call 800-214-3245

- In person: Visit our steel yard and showroom in Hutchins