Essential Steel Shapes for Building Strong Structures

Learning how to build with steel will take your construction and fabrication projects to the next level. Steel is a strong, durable material that you can use in lightweight building construction (think sheds, outdoor workshops, etc.) or to create custom shelving, workbenches, trailers, fencing, staircases — the list goes on.

If you’ve never worked with steel, it can feel slightly foreign at first. What’s important to know is that all structural steel comes in standardized shapes. These shapes derive their names from the appearance of the steel at its cross section. Structural steel shapes are measured and sized according to industry standards established by the American Society for Testing and Materials (ASTM) International, which also sets the tolerances for sizing. How you join the steel together — bolting versus welding — largely depends on the shapes you choose.

Compare Structural Steel Shapes for Your Project Needs

Most of the steel used in construction and fabrication is carbon steel, an alloy of carbon and iron. The shape of the steel doesn’t affect its durability and corrosion resistance. However, it does affect its performance in various applications.

Some steel sections perform better under different loads. For example, something that works well under tension (as a horizontal beam) won’t always work as well under compression (as vertical reinforcement). Here’s how to choose the right structural steel shape for your project.

Steel Plates and Flat Bars

A simple steel plate made from solid rolled steel is one of the most basic structural steel shapes. It is commonly used for industrial applications and general construction, as well as for structural support, ramps, general fabrication, walkways, and transport equipment. Plates are often much wider and thicker than strips.

A flat bar, although it looks like a narrow steel plate, is typically thicker and stronger. It is ideal for braces, framework, plates, supports, and straps. Flat bar strips are easy to work with and suitable for welding, cutting, bending, and drilling. You can use a flat bar horizontally or vertically. It’s a versatile choice for many steel construction projects. Its manageable size and form make it easy to use for beginners, while providing the strength and durability required for several applications.

- Good for lightweight construction but not ideal for heavy loads

- May lack stability when used upright in longer lengths

- Works well as bracing for larger steel structures

- Can be difficult to anchor in concrete or stone

Angle Irons

An angle iron is like a flat bar that has been bent lengthways into an L shape. The “legs” of the L come in many different sizes, some equal in length and others unequal. The size you choose will depend on what you want to support.

Very small angle irons (such as 1/2″ x 1/2″) are suitable for reinforcing wooden corners, artwork frames, and chicken coop doors. Larger ones (2″ x 2″ and larger) are strong enough to be used as legs and framing for shelves and workbenches. A full-blown construction project would require angle irons with at least 5″ legs.

- Ideal for bolting into corners, brackets, framing, etc.

- Can be used horizontally and vertically

- May be difficult to cut the L shape perfectly

- Imperfect metered cuts can create gaps at the joints of the frame

Steel Channels

Steel channels are C- or U-shaped in cross section and offer slightly more strength than an angle iron. The open-sided shape means it’s just as easy to bolt onto walls and other flat surfaces. Unlike angle irons, however, steel channels have two supporting flanges (legs) that protect the steel from bending.

They are best suited for horizontal applications, such as door and window construction, reinforcement for staircase landings, or tracks for sliding doors and gates. They also work well as a non-load-bearing substructure for wall and roof panels.

- Cutting a perfectly straight edge takes practice, just like cutting an angle iron

- Not ideal for vertical use unless in very light loads because it is prone to buckling

- Easy to clamp together; welding perpendicular surfaces is a breeze

- Heavier and bulkier than an angle iron, and often more expensive

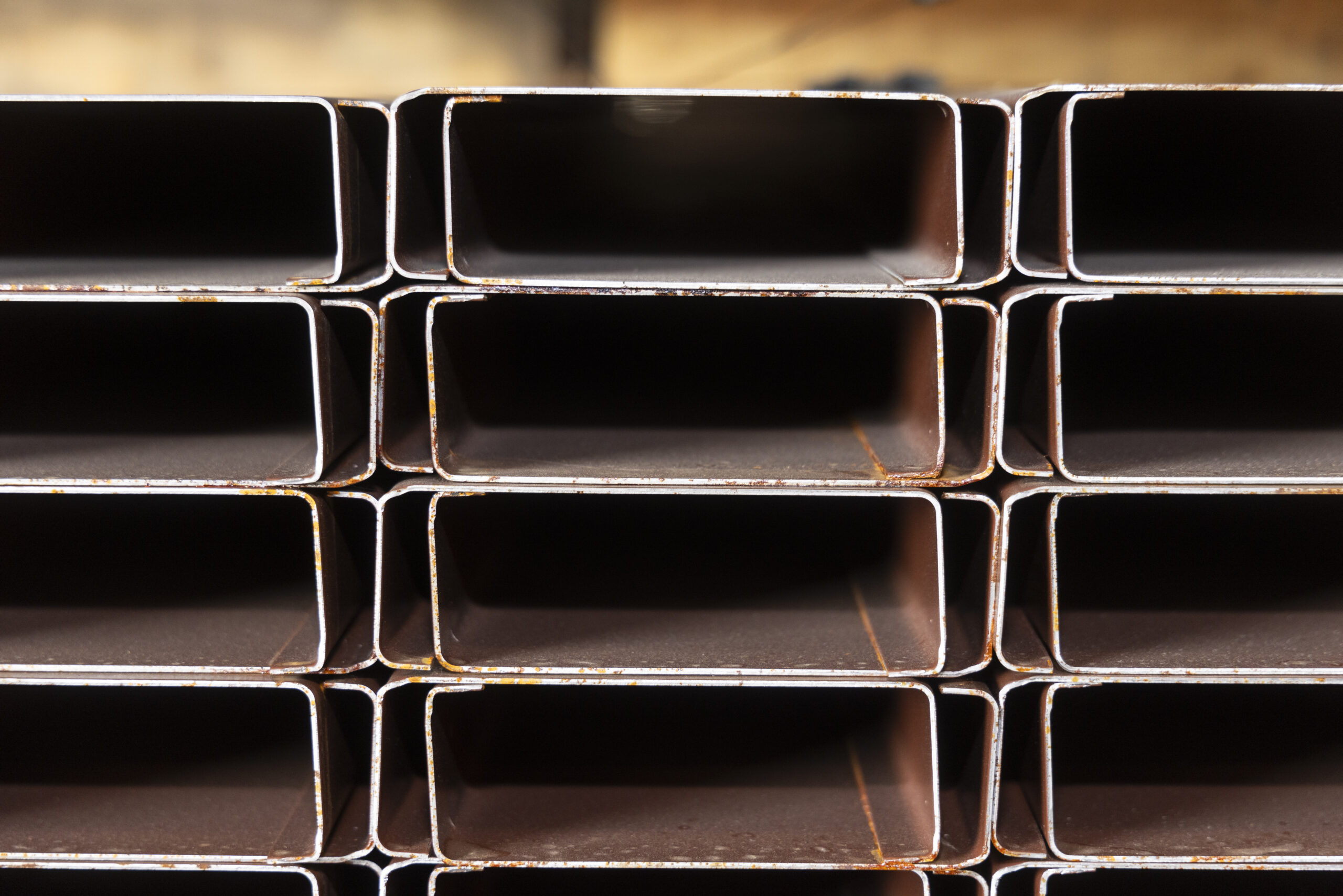

Square Tubing

Square tubing is one of the strongest structural steel shapes because of its rigid corners and equal-sided geometry. The hollow square tube distributes load evenly across its four sides. It performs well under compression (for example, steel used vertically with weight applied from above). It is most commonly used in furniture making and fencing. The neat square faces make modern-looking steel frames for chairs, desks, and coffee tables. They’re also great as balcony railings.

- Has a more finished look than angle irons and channels

- Won’t twist or buckle and can support plenty of weight

- More challenging to weld or bolt from the inside because of the closed-off section

- Can easily be dented on the long sides

Round Tubing and Bars

Why would you choose round steel bars or tubes over square ones? The answer, as always, depends on the type of load you want to support. Rounded steel products — both hollow and solid — are excellent against twisting forces. Anything that rotates, like drive shafts, locking mechanisms, and axles, should be cylindrical.

You can also use round steel where ergonomics are essential. For example, in handrails, rounded edges are much more comfortable to hold than square ones. Round bars and round tubing are also an excellent choice for vertical posts because they’re easy to anchor in concrete.

- Has a finished look and ergonomic feel

- Easy to bend for projects that call for arches and organic shapes

- Good wind resistance, more stable as fence posts, etc.

- Use hollow round tubing to hide electrical cables and pipes

Get Steel-Working Advice

Eagle National Steel offers premium-quality structural steel products for home fabricators, DIY enthusiasts, and the construction industry at large. We can help you select the ideal steel for your project, taking into account its strength, span, and ductility requirements. Visit our service center in Hutchins, Texas, for expert advice on steelwork, or contact us for more information.